[Original Truck House] Why are some shifts so smooth and effortless? Many card friends will simply operate the gearbox when purchasing vehicles, and find that some products have light and smooth gearbox gears, while others have to work hard to push the gears in, and the operation is a little stuck and not smooth enough. So what is the main reason that affects the shift feel of gearbox? Among them, synchronizer has played a great role.

I believe many old drivers are already very familiar with the operation mode of "two-foot clutch", mainly because this kind of gearbox is not equipped with synchronizer. UpshiftIn the neutral position of stop for a minute, the clutch needs to be lifted during this period.Synchronize the clutch plate with the flywheel to reduce the impact during gear shifting and ensure the smoothness during gear shifting.When downshifting, the gearbox needs to be in neutral position, and the refueling door,While keeping the clutch lifted,To reduce the speed difference of gears..

Use "Two-foot clutchThe purpose of "isThe rotation speed is more matched with the selected gear and the required speed,Reduce or increase the rotating speed of the driving gear in the gearbox,The rotating speeds of the two gears to be engaged in the gearbox are kept close, so as to realize a more stable and light shift feel and reduce the internal speed of the gearbox.Wear of parts, prolong service life.

For novice drivers, it is still very difficult to master the shifting skills skillfully and accurately, so the appearance of synchronizer in the back solves this problem well.

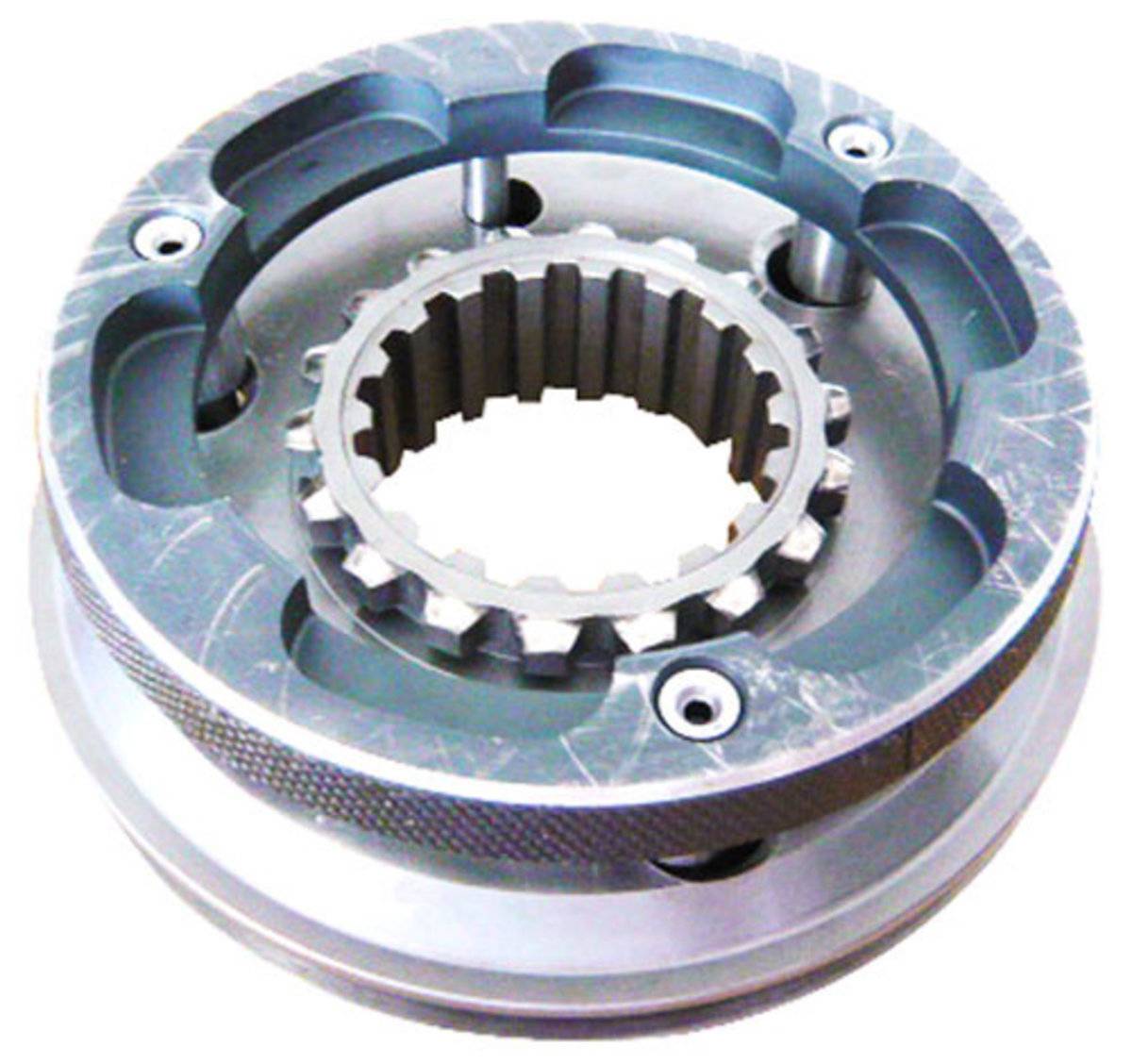

There are three common structural forms of gear shifting devices: direct sliding gear type, engagement sleeve type and synchronizer, and the synchronizer gear shifting device is widely used at present.At present, inertial synchronizer is widely used in trucks, which can be divided into lock ring type and lock pin type.So what is its main function?

In fact, we can see from the name that its main function is "synchronization". Because the input shaft and the output shaft of the gearbox rotate at their own speeds, the speed is inconsistent. If the slow-rotating gear is forced to mesh with the high-speed rotating gear, it will inevitably lead to impact, collision, tooth punching and other phenomena, and the rush and noise during gear shifting will be obvious.

Synchronizer can realize the speed matching between gear and shaft to avoid these situations. We can think of it as being inFriction plates arranged on the combination sleeve and the gear set,Synchronization is achieved by friction,It is equipped with a special mechanism to ensure that the engagement sleeve and the spline gear ring to be engaged can not contact before reaching synchronization, thus avoiding the impact between teeth.

SynchronizerCan rotate with the toothed hub and can also slide on the shaft. When we step on the clutch pedal, the gear bushing will push the synchronous gear ring to the bevel gear. Due to the friction between the synchronous gear ring and the bevel gear, the speed of the gear will be consistent with the speed of the shaft. At that time, the bushing will further lock the gear, so the gear is effectively and smoothly locked by the shaft.

The friction surface of the synchronizer friction plate is tapered, so that before the straight teeth contact with the vertical teeth of the disc, the friction can be carried out in advance and the effect of energy transfer can be achieved. Simply put, whenThe shift fork pushes the sleeve to squeeze the synchronizer to be combined with the gear,Transfer the energy from the side with faster rotation speed to the side with slower rotation speed, so that the two can achieve synchronous rotation speed.

The synchronizer can ensure that the circumferential speed of the engagement sleeve and the gear ring to be engaged is quickly equal during gear shifting, shorten the gear shifting time of the gearbox, and prevent them from engaging before synchronization, thus eliminating the impact during gear shifting, and also bringing light gear shifting feel, prolonging service life and reducing wear.

At present, inertial synchronizer is mainly divided intoThere are two kinds of lock ring and lock pin. What’s the difference between them?

Lock ring inertial synchronizer

The lock ring synchronizer is composed of a joint sleeve, a spline hub, a lock ring, a slider, a positioning pin, a spring, etc. It has a compact structure andThe radial dimension is small, the friction torque between conical surfaces is small, and copper material is commonly used, so the shifting force is small, and it is often used in high-speed gears of cars, light trucks or heavy vehicles with little torque transmission.

Lock pin inertial synchronizer

The lock pin synchronizer is mainly composed of joint sleeve, cone ring, cone disk, lock pin, positioning pin, positioning steel ball and spring.Commonly used steel materials, whichThe structure allows the use of larger friction cones, and larger friction cones can generate larger friction torque, which also shortens the synchronization time. Therefore,Can bear more shifting energy,Mostly used in medium, heavy or low gear.

Generally speaking,Lock ring sumThe working principle of the lock pin type is basically the same, and the purpose of "synchronization" is achieved by using the cooperation between the friction cone ring and the inclined plane on the lock pin.

There are also many card friends who believe that the gearbox without synchronizer will be more durable, reliable and cheaper. Although the gear will be noisy and not smooth enough, as long asThrottle and clutch,Under the condition that the engine rpm and speed are well matched, the gear will not ring, but this will test the driver’s skill and experience.

Another part of the card friends said that although the price will be more expensive, the synchronizer has higher technical content and plays a buffering role in the shift process, which can effectively reduce the sense of shift frustration and make the gearbox shift smoother and lighter. A few fingers can complete the shift. However, we should be careful not to use brute force when using it, and maintain the gearbox according to the specified time, and use the special lubricating oil for the gearbox to keep the gear machinery inside the gearbox in a good state.

● Editor’s note:

Synchronizer plays a good coordinating role between gears in gearbox, which can help card friends to shift gears more easily, andNow the gearbox equipped with synchronizer has become a trend, and the mainstream products have been equipped with synchronizer one after another. At this stage, the technology update iteration is fast. A few years ago, who would have thought that AMT automatic gearbox could develop so rapidly in China? In short, following the trend of the times, new technologies appear for the purpose of reducing work intensity and improving comfort and safety. Card friends, does your gearbox have a synchronizer? (Text/Gong Yixin)